American Standard for Cold Rolled Mild Steel

Author:ALEX

American Standard for Cold Rolled Mild Steel

Abstract:

The American Standard for Cold Rolled Mild Steel is a critical reference in the steel industry, providing guidelines and specifications for the production and use of cold rolled mild steel. This article aims to provide a comprehensive understanding of the American Standard for Cold Rolled Mild Steel, discussing its background, significance, and practical implications. By exploring four key aspects of the standard, this article aims to shed light on the technical specifications, material properties, manufacturing processes, and applications of cold rolled mild steel. The  findings presented in this article can serve as a valuable resource for engineers, researchers, and professionals involved in the steel industry.

findings presented in this article can serve as a valuable resource for engineers, researchers, and professionals involved in the steel industry.

Text:

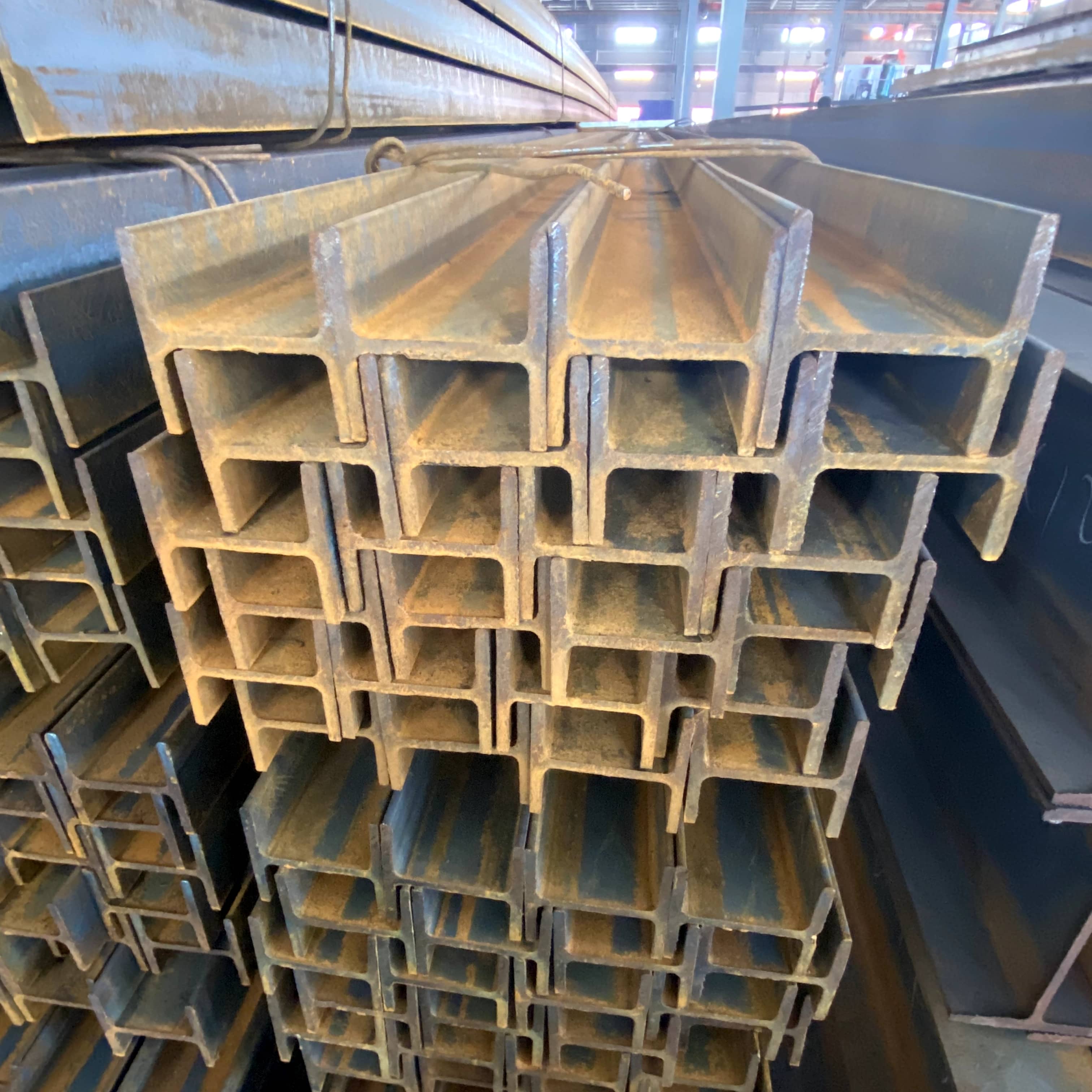

1. Technical Specifications of Cold Rolled Mild Steel

Cold rolled mild steel is an essential material used in various industries due to its excellent strength, formability, and versatility. The American Standard for Cold Rolled Mild Steel sets forth the technical specifications that ensure the quality and consistency of this material. These specifications provide guidelines regarding the chemical composition, mechanical properties, and surface finish of cold rolled mild steel. For instance, the standard specifies the allowable carbon content, maximum tensile strength, and minimum elongation percentage, ensuring that the material meets specific performance requirements. Additionally, the standard outlines the permissible variations in dimensions, shape, and characteristics, enabling manufacturers to produce accurate and uniform cold rolled mild steel products.

2. Material Properties of Cold Rolled Mild Steel

Understanding the material properties of cold rolled mild steel is crucial for its successful application in different sectors. The American Standard for Cold Rolled Mild Steel offers comprehensive insights into these properties, which include strength, toughness, ductility, and weldability. Cold rolled mild steel exhibits superior strength and hardness compared to hot rolled mild steel due to the cold working process. The standard defines the minimum and maximum values for yield strength, tensile strength, and hardness, ensuring that the material possesses the desired mechanical properties. Moreover, the standard focuses on enhancing the ductility and toughness of cold rolled mild steel, making it suitable for various forming and fabrication processes. Furthermore, the standard provides guidance on the weldability of this material, ensuring that it can be effectively joined using different welding techniques.

3. Manufacturing Processes of Cold Rolled Mild Steel

The American Standard for Cold Rolled Mild Steel also delves into the manufacturing processes involved in producing high-quality cold rolled mild steel. These processes include pickling, cold rolling, annealing, and finishing. Pickling involves the removal of impurities and oxides from the surface of the hot rolled steel, ensuring a clean and uniform substrate for subsequent processing. Cold rolling, the primary process in producing cold rolled mild steel, involves reducing the thickness of the hot rolled steel through a series of rolling operations. Annealing, a crucial step, enhances the material's ductility and removes internal stresses caused by cold working. Finally, various finishing techniques, such as skin passing and temper rolling, are employed to further improve the surface quality and flatness of the cold rolled mild steel.

4. Applications of Cold Rolled Mild Steel

Cold rolled mild steel finds wide-ranging applications in industries such as automotive, construction, appliances, and manufacturing. The American Standard for Cold Rolled Mild Steel elucidates the suitability of this material for different applications, highlighting its advantages and limitations. In the automotive sector, cold rolled mild steel is widely used for the production of automobile frames, body panels, and chassis components due to its high strength-to-weight ratio and formability. In the construction industry, this material is employed for structural members, roofing, and cladding due to its durability and corrosion resistance. Additionally, cold rolled mild steel is extensively utilized in the manufacturing of household appliances, furniture, and packaging materials. The standard provides insights into the specific requirements and performance criteria for each application, ensuring that the cold rolled mild steel meets the desired specifications.

Conclusion:

In conclusion, the American Standard for Cold Rolled Mild Steel serves as an essential reference in the steel industry, providing guidelines and specifications for the production, properties, and applications of cold rolled mild steel. Through a comprehensive exploration of the technical specifications, material properties, manufacturing processes, and applications of this material, this article aimed to provide a comprehensive understanding of the American Standard for Cold Rolled Mild Steel. The insights presented in this article are valuable for professionals involved in the steel industry, enabling them to make informed decisions regarding the selection, production, and utilization of cold rolled mild steel.

add your comment